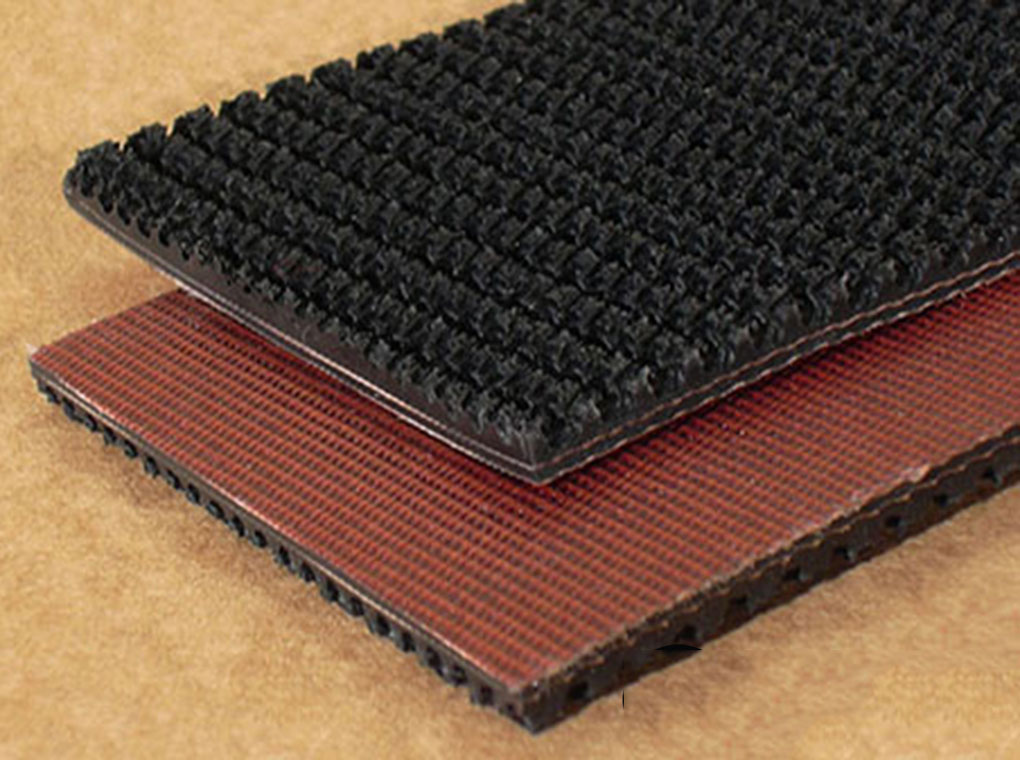

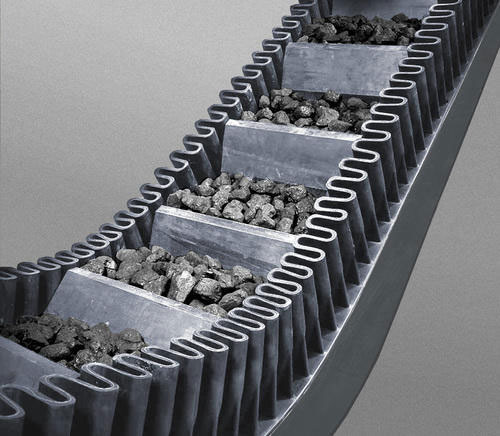

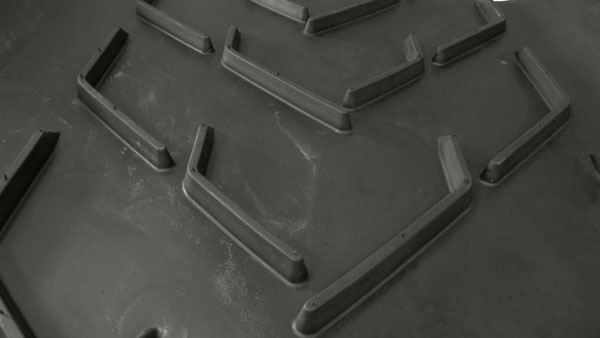

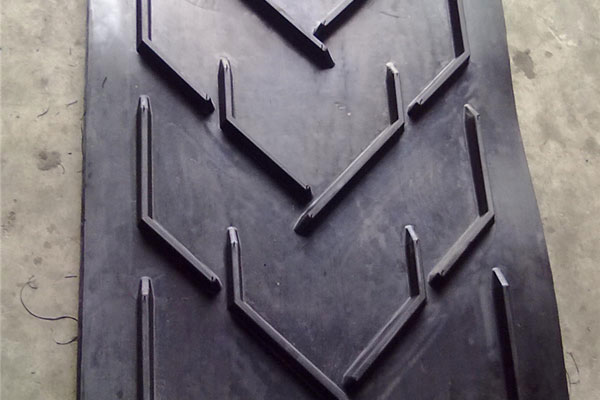

Our customers can take advantage of an optimal quality range of heavy duty conveyor belts, which express various hot and oil contents, especially high quality wear, including coke, hot fertilizer, asphalt, grit, ore, coal, rocks and Designed to be used extensively. This belt has a bare back (slider bed) to convey stones, clinker and riprap etc., logs and other forest products, which ensures other operations.

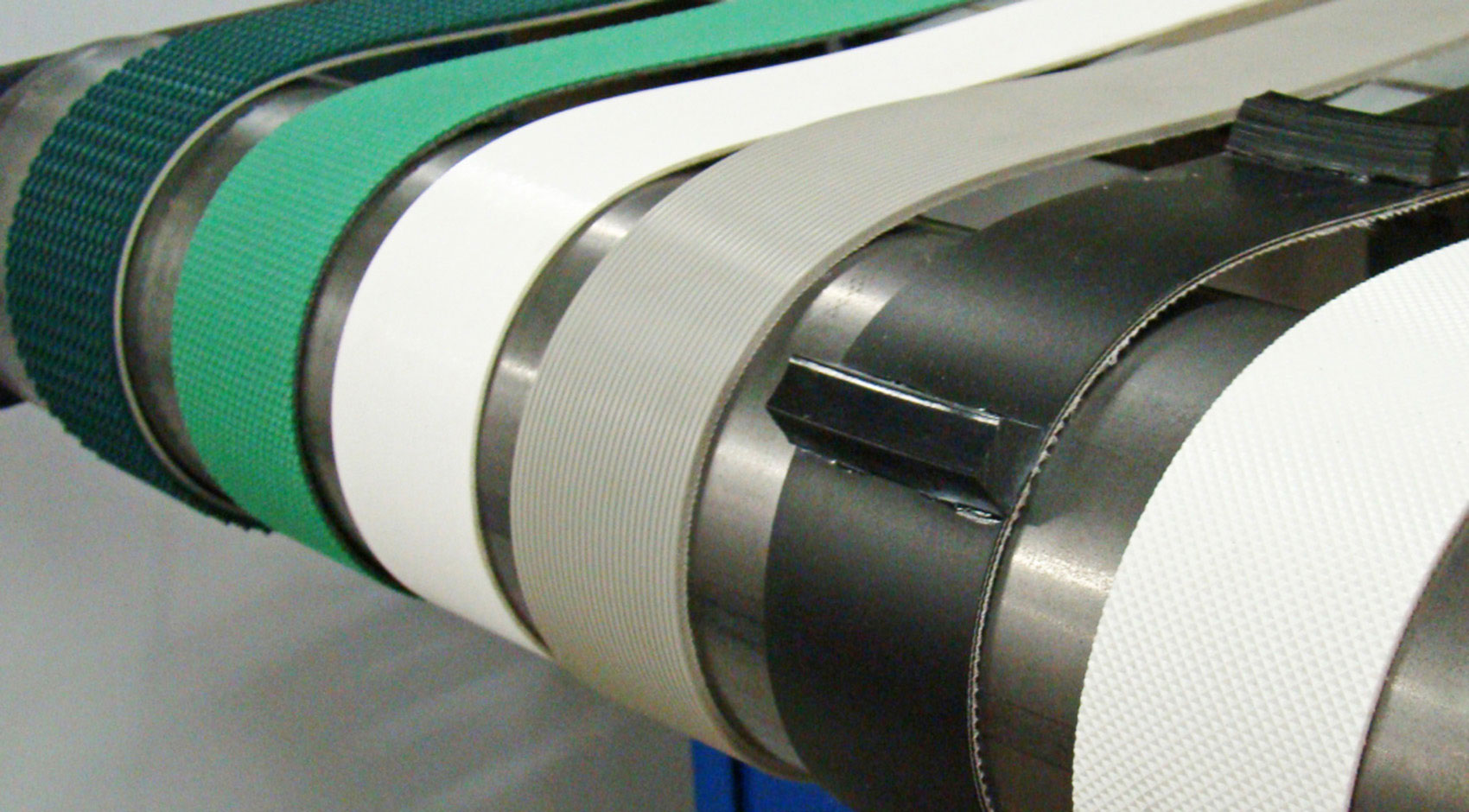

Our heavy duty belts are precise engineers and under strict testing on tensile strength parameters, elongation on brakes, maximum friction loss etc. Find these applications in these heavy duty conveyor belt airports, shipyards, thermal plants, construction, mining, processing and various other. . The industry is specializing in offering these heavy duty belts in both standard and customized specifications.

Features:

Heat resistant

Oil resistant

Special wear resistant covers

Ideal for carrying sharp & rugged materials

Application Areas :

Pharmaceuticals, building construction industry, sorting and installation of goods, baking, making biscuits and tiles, canning treadmills, fruit and vegetable materials fishing, glass and insulation.